Equipment

The Creaform 700 is a hand held scanner and is small enough to be a carry-on for a flight, but powerful and accurate for large and complicated machined parts.

This scanner has a metrology grade unit with the following specifications:

• Accuracy: Up to 0.0012 in

• Volumetric Accuracy: Up to 0.0007 in/ft

• Resolution: 0.0020 in

• Measurement Rate: 480,000 measurements/s

• 7 Lasers

• Post-Processing Software: VX Elements and Solidworks

The Process

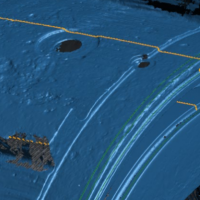

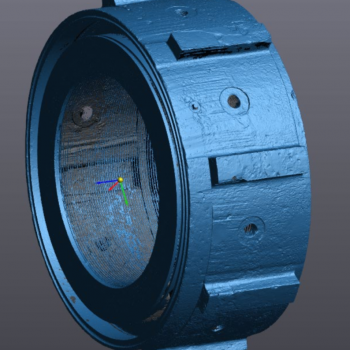

1. Apply adhesive or magnetic targets to the part (see the large nut on the right). These position the part for the scan.

2. Laser Scan the part

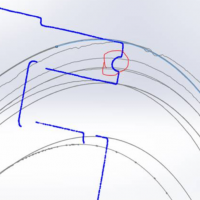

3. Post-Process the Data

4. Make a Solid Model using the post-processed data.

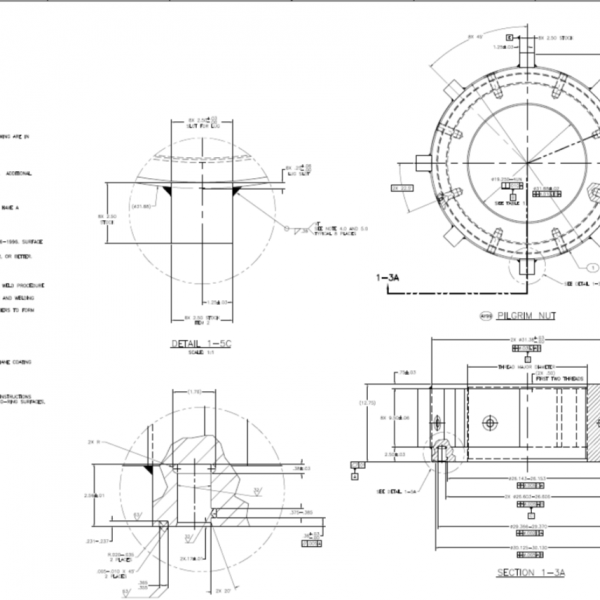

5. Make a dimensioned print of the part.

3D Laser Scanning and Post-Processing the Data

The scanning session for this part (actual scan time) was about an hour. Note the detail in the part: The scanner will pick up manufacturing defects and surface corrosion. Post-processing the data for the intended outcome involves aligning the part, making planes, and cutting cross sections in VX Elements (Scan Software). The part is then re-created in Solidworks so a full feature tree is available for easy modification, as needed.

Making the Dimensioned Print

• The print can be made from the parametric model.

• Export file types include: *.STEP, *.IGES, *X_T and most other 3D file types

• 2D Exports of the print can include PDF, DWG, and DXF.